Basic Info.

Model NO.

R-150DT

Calibrating Method

Standard Hardness Test Blocks

Rated Voltage

220V (or 110V)

Support Language

English or Chinese

Customized

Customized

Display

8′′ Touch Screen

Resolution

0.1hr

Quality Judgement Function

Yes

Hardness Conversion

Yes

Loading

Automatic Loading - Dwell - Unloading

Product Name

Hra Hrb HRC Digital Rockwell Hardness Testing

Load Selection

on Touch Screen

Structure

Close Loop, High Precision Load Cell

Transport Package

Plywood Box

Specification

560x220x750mm

Trademark

EBP

Origin

Zhejiang, China

HS Code

9024102000

Production Capacity

90 Sets Per Month

Product Description

Diamond Indenter HRC Digital Rockwell Hardness Tester With USB

Product Features:

Product Features:

1. Modern and beautiful appearance, stable structure

2. Touch screen interface, easy operation, English language

3. Close loop structure, with high accuracy load cell instead of weights. Unnecessary for installing weights and debugging, installation more easy.

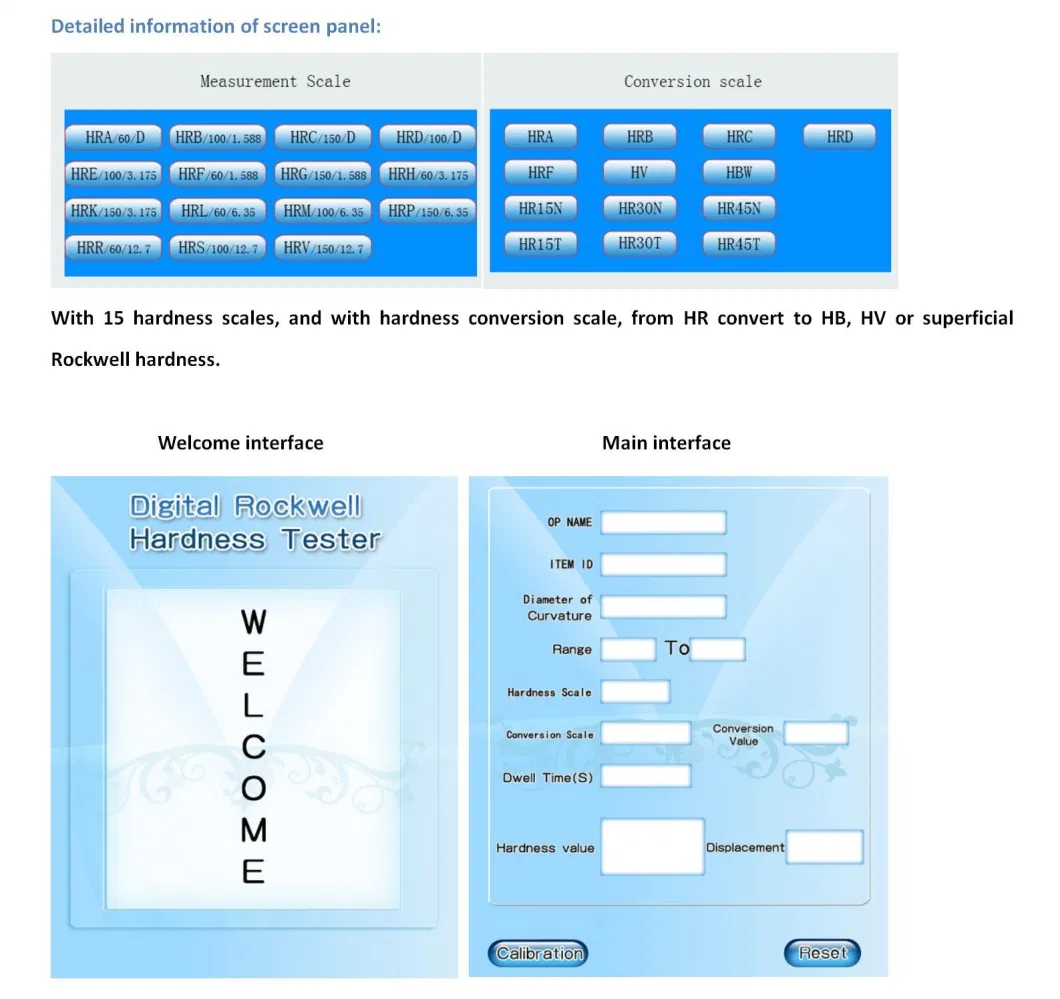

4. Automatic loading - dwell - unloading

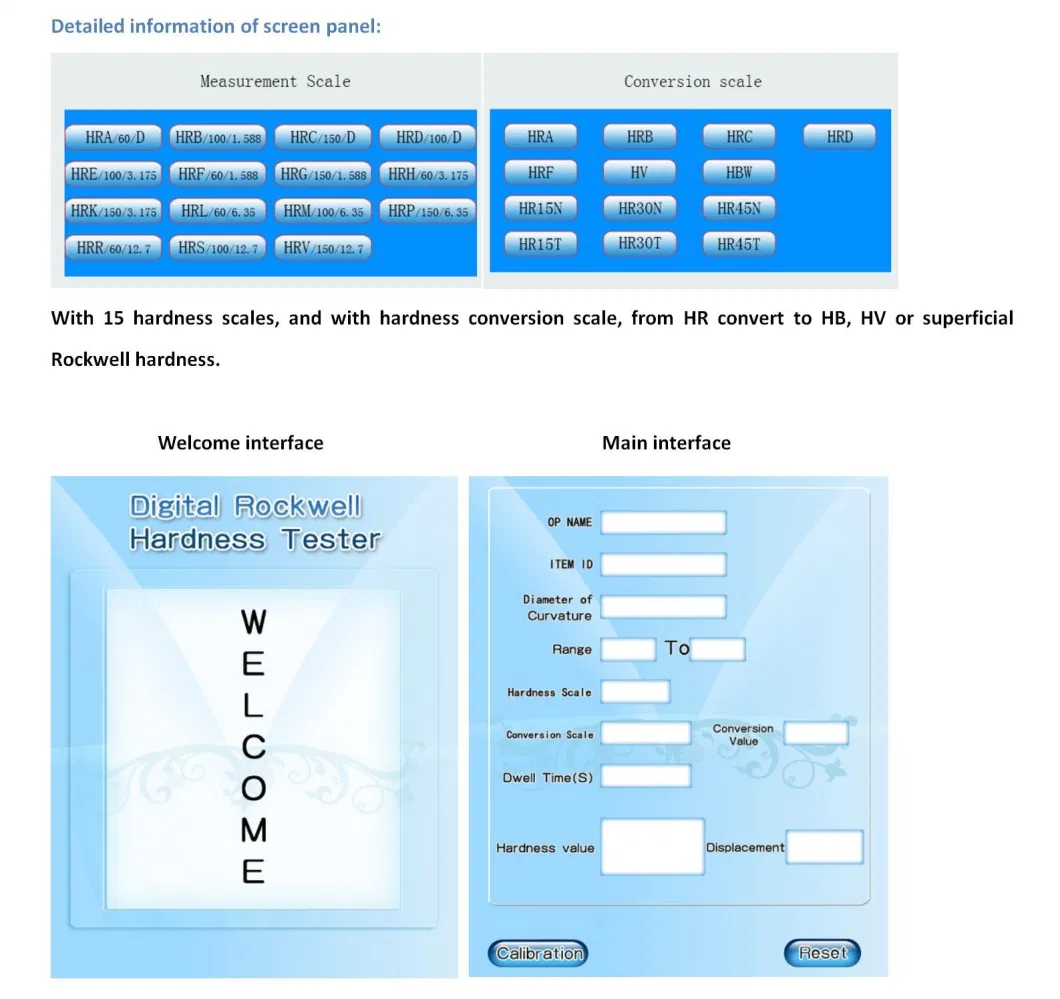

5. All Rockwell scales, total 15 hardness scales

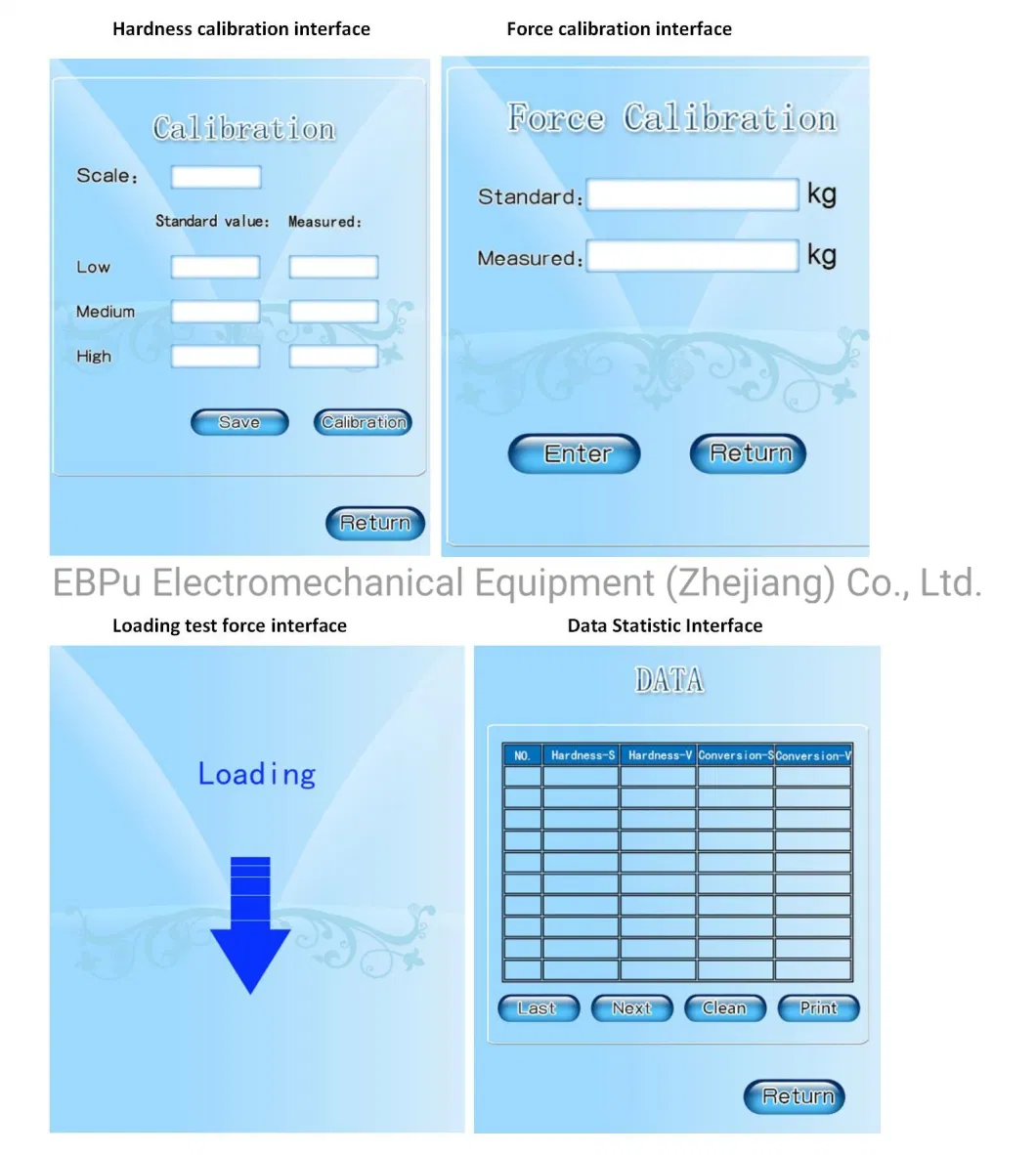

6. Automatic correction of high, medium and low hardness numbers

7. Automatic correction of load, with the force accuracy increased by a numerical level

7. Automatic correction of load, with the force accuracy increased by a numerical level

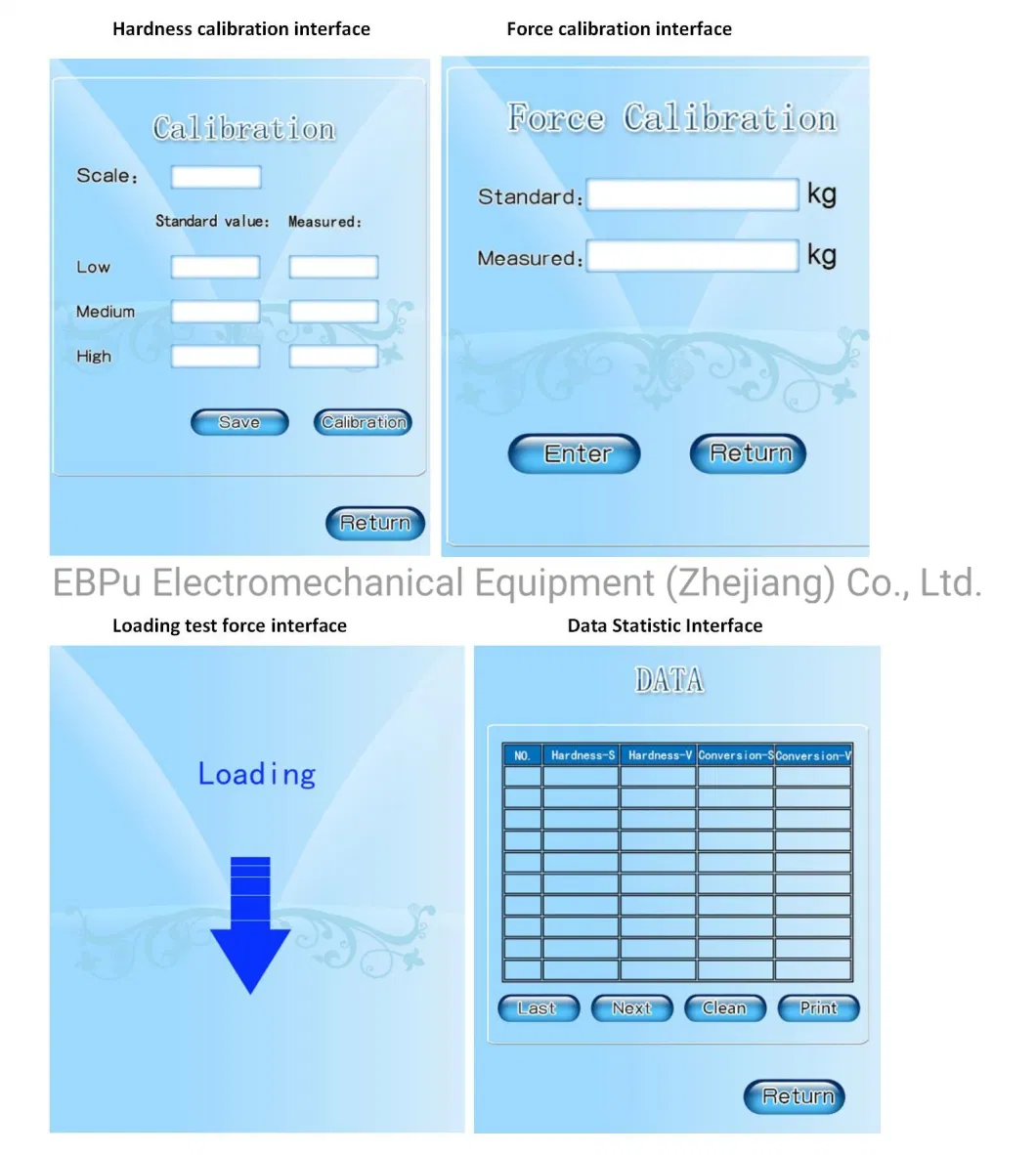

8. Data stored in USB flash disk, EXCEL format, easy for compiling and processing

9. Adopt the modular design, easy maintenance

Demo video on YouTube: https://youtu.be/UmlJLRwhkJU Application Fields:

1. Quality control of Industrial production (machinery manufacturing, metallurgy plants, etc.)

2.Research & Inspection of Inspection Institution and universities laboratories.

3.Ferrous and nonferrous metals, Hardened steel, tempered steel, annealed steel, hardened steel, sheet of various thicknesses, carbide materials, powder metallurgy materials, etc.

Technical Parameters:

| Model | R-150DT |

| Initial Test force | 10kgf (98N) |

| Main Test force | 60kgf (588.4N), 100kgf (980.7N), 150kgf (1471N) |

| Hardness scale | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRP, HRR, HRS, HRV |

| Conversion scale | HRA, HRB, HRC, HRD, HRE, HRF, HV, HBW, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

| Dwell time | 0-99s |

| Load value error | <0.5% |

| Hardness testing range | HRA: 20-88, HRB: 20-100, HRC: 20-70, HRD: 40-77 HRE: 70-100, HRF: 60-100, HRG: 30-94, HRH: 80-100 HRK: 40-100, HRL: 100-120, HRM: 85-115, HRR:114-125 |

| Resolution | 0.1HR |

| Executive standard | BSEN 6508, ISO 6508, ASTM E18, GB/T230 |

| Test space | 220*200mm (H*D) |

| Hardness reading | LCD display |

| Data output | USB flash disk in Excel format |

| Power supply | AC220V, 50/60HZ |

| Net weight | 70kg |

| Size | 560x220x750mm |

| Gross weight & Packing size | 780x470x940mm 90kg |

Standard Accessories:

| Name | Quantity | Name | Quantity |

| Diamond Rockwell indenter | 1 | Ball indenter with the diameter of 1.5875 mm | 1 |

| Hardness block (HRB, HRC high, HRC low value) | 3 | Large, medium, V-type testing table | 1 for each |

| Power line | 1 | Dust-proof plastic housing | 1 |

| USB flash disk | 1 | Operating Instruction, Product Qualification Certificate | 1 for each |

If want to save test data to computer and generate test report, please additional purchase our data transfer software: